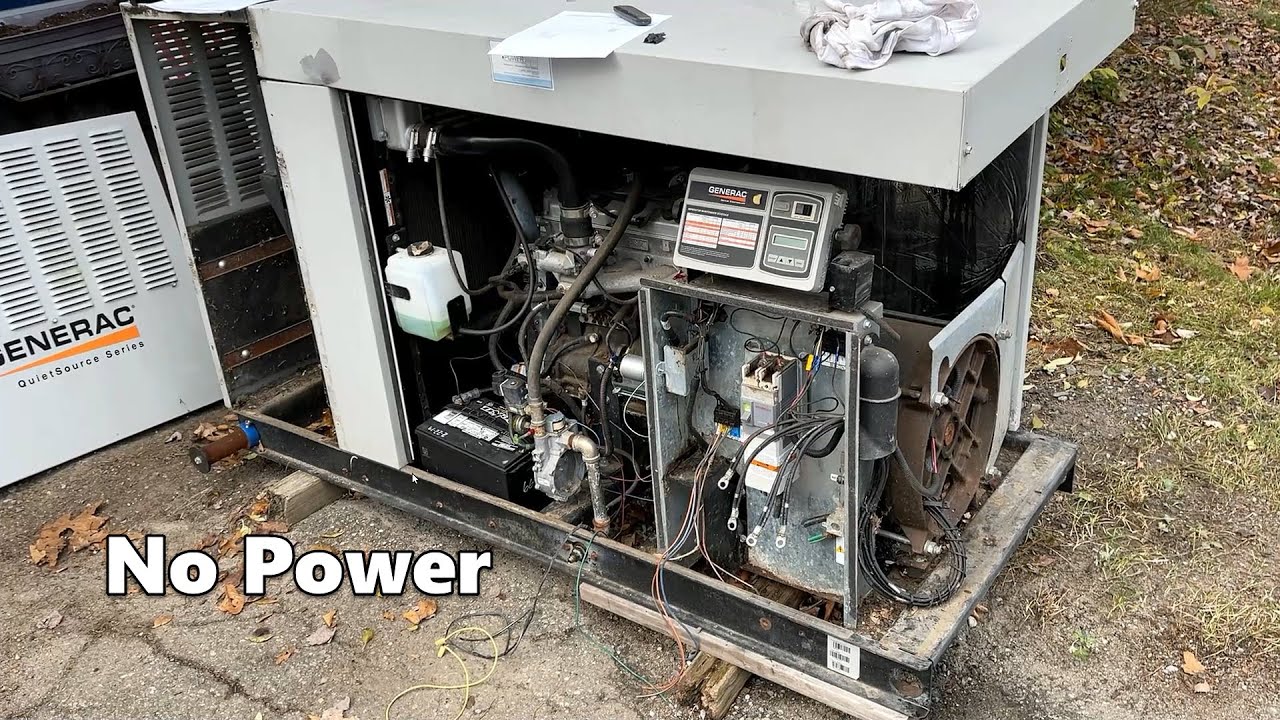

Hey guys welcome back So today i’ve got something a little bit Different this is a 36 000 watt generac Generator and It actually doesn’t belong to me It belongs to rob who’s standing right Next to me say hello rob hello Anyway he got a heck of a deal on this Brand new they sell for about thirteen Thousand dollars i think he paid about 200 and that’s for good reason it Doesn’t make power you know that said There’s plenty of room here to put some Money into this and get this working Again now he has done some testing on it He believes the stator is bad and of Course the stator is still available They sell for about Two thousand dollars up to three Thousand depending upon where you look And You know in this case it might be worth It so rob wants a second opinion so i’m Gonna Take a look let me get you set up a Little bit better and get going on this So there’s not too much to test down Here i mean we have the brushes there’s Actually two sets and the slip ring so We can check the rotor from here as far As the stator goes all the wires Actually go up into this electrical Panel here and They terminate right here now there are

A lot of Broken or i should say broken a lot of Cut wire so the fact that he had this Running and it wasn’t making power Isn’t necessarily a bad stator but This was sold to him as a generator that Doesn’t make power and when he fired it Up the engine sounded good but it did Not Make any power so i tend to believe that We do have bigger issues down there with The stator Empowering this generator it is a Four-cylinder Mitsubishi engine which i find a little Surprising i thought generac made their Own engines on stuff like this anyway it Is electric start this one is propane Powered and this is also liquid cooled And i was kind of surprised to find a Turbo Sitting Way over there in the corner so It’s a decent engine He has had it running so that is not the Issue We need to take a closer look at this So we’ll check the rotor first that most Likely is good A good rotor should test at about 8.1 Ohms [Applause] We’re at 7.5 so that seems to be good We’ll check it to ground

And there’s a connection to ground at 76.00 So most likely the rotor Is bad [Applause] As far as the stator goes these are the Main windings coming out here we have Leg one I believe are these two wires And leg two A healthy stator on this should come in At about 0.4 ohms And That’s pretty much a dead short It’s the same as Connecting these together so the stator Would seem to be bad but let’s just Check leg two That’s about the same Let’s check them to ground [Music] So just cleaned off a spot here we’re Gonna check leg one to ground Ideally there should be no connection But we do have a connection it’s about 400 000 ohms All right let’s check lake two A little bit higher about 500 000 ohms Unfortunately the damage to the Powerhead is Much more severe than both rob and i Thought we had assumed that yeah the Stator would probably be bad

But the rotor kind of surprised me so This generator needs a new stator and a Rotor which doesn’t leave a whole lot of Meat left on the bone i mean this Generator in used condition would Probably sell for about six thousand Dollars your new stator is three Thousand a new rotor i actually haven’t Priced out but i’m willing to bet It’s close to the cost of that stator so You know all in Best case scenario I think we’d break even getting this Thing fixed so do a bit of research Potentially that rotor doesn’t cost as Much as i think it does And potentially There’ll be a part too Anyway since i’m here rob does have some Rusty old junk including a Kohler generator that was made probably In the early 50s And he has another Antique engine as well so we’re gonna Fire those up and just show you how Those work Okay so this is a myrick eclipse Engine It’s an oil field engine From probably the late 19 Late teens Early 20s I would work on the oil well either

Pumping oil or pumping water off the top Of the oil well It’s Fueled by it would have been fueled by Natural gas because that was a byproduct Of the oil drilling process Now we run it on a Barbecue tank It’s a hot tube engine So we’re going to start a burner and It’s going to heat a stainless steel Tube here to a red hot When the combustion gas gets pushed up Into that tube by the compression and Hits that red spot red hot point it’ll Ignite Takes a few minutes for it to warm up But we’ll get it lit here So that’ll take about 10 minutes to get Hot And then we can start it Where’d you find this A friend of mine collects them This was This was a little one for him he has a Bunch of Massive Oil field engines Basically the size of a small car he’s Got i think four or five of them at his House and he had he had three of these That he came Came across and uh I really liked it so he

He gave me one it was all in parts we Had to put it together okay that’s my Next question so it wasn’t in running Condition it was something that it was It it’s this one is bits and pieces of Myrick engines I think the This part is the original The head is not the original the hot Tube Is from another engine the plumbing of Course is all stuff that i did I had to build an exhaust valve for it Because that was In pretty bad shape But it’s a it’s a conglomeration of Different myrick engines it’s not Original it’s probably not very valuable But it’s fun can i show these though It’s interesting the head cooling just Uh yeah it’s Air-cooled this one this is a clutch That would have been belted to a pump Jack Um there’s there would have been a big Lever here that you engage the clutch With And it would just They would run for years with very Little maintenance [Music] We might have trouble because it’s a Little bit windy but So

So this one was built in uh The wall of myricks were built in olean New york Which is a couple hours North And then this one worked in a Oil field somewhere in pennsylvania And made its way back here Once it warms up it’ll run a little bit Better the hot tubes would burn out Occasionally Or eventually Um You know They probably have to put new rings in From time to time But really No no and you you know you’d have one Guy that would come around a couple Times a day and oil everything up and They would literally run them for years Almost almost non-stop because when they Stopped they weren’t making any money It’s a round belt from mcmaster i Couldn’t find one i couldn’t find a Black one or originally it would have Been a leather belt Can’t really find them anymore I’m sure A little uh along like that all day Sure I actually i have it sitting out here Because i want the plumbing To rust up a little bit

All right so this one’s a little bit More up my alley this is a four-cylinder I believe gas-powered Generator it is a kohler Made most likely in the late 40s or Early 50s And rob actually uses this one To power his house so we’re going to Fire it up Probably hook up the multimeter and just See what we’re getting sure i actually Did not bring the kilowatt so We’ll be able to check The voltage but not the hertz sadly So let’s fire this thing up and see how It sounds well this one’s a little bit Simpler to start up Wow Very nice So [Applause] [Music] Very nice [Music] Got a little electric start there [Music] Very cool These were actually very popular in uh Marine applications They would have cooled them with sea Water and in the bottom of a boat Somewhere oh yeah there’s uh There’s not a lot of them that are

Set up for Home use but there is uh There’s still quite a few of them around In marine applications in fact there’s a Couple places uh In florida where i buy parts that are Primarily marine dealers All right not too bad 117 volts 61.5 Hertz It’s perfect Not a bad setup i mean this thing for 5000 watts Four cylinders that is not something you Will see today Anyway i am interested in What’s in here so we’re gonna pull this Cover off and just take a look at the Electronics inside All right you ready we’re not sure what We’re going to find in here Hopefully not a mess A little bit different inside From modern generators so i don’t know Exactly how all this stuff is tied in There is actually a circuit diagram here But it is a bit hard to read But from what i can see i mean obviously We have a transformer here This looks to be a bridge rectifier we Got four Wires going into it And an adjustable resistor right there Most likely for adjusting the power Output

And another resistor here on the outside The rest of it just a few contactors Starter solenoid and looks like some Connections to the charging system but You know overall Fairly straightforward design You know this engine Is built very well you know You would not see something like this Made today For a 5000 watt generator So that’s pretty much it i mean maybe Not the happy ending everyone was hoping For but we did get to see some cool toys And who knows Maybe they’ll be a part too Hope this video helps someone Thanks for watching Not so fast i made a rookie mistake here I left the brushes connected to that Rotor and the wire going into the Control panel i thought was disconnected And whether it was or not Almost doesn’t matter because This wire Right here Connects over To the brushes and that is why I got a connection to ground of 76 ohms Thankfully rob Uninstalled the stator and the rotor And ran Another test let me show you So here rob is testing between the slip

Rings ideally it should be 8.1 ohms and He’s getting just about that it is Temperature Related and it is a cold day so 7.8 7.9 Should be fine And now he’s checking The slip ring To ground And this is a low voltage test there is No connection and according to generac That is good You know now he is using a high voltage Test At 500 volts between One of the slip rings and ground and There is a connection it’s Close to 60 million ohms you know i’d Like to see that higher but I think this rotor is good So Rob has placed an order For a new stator and potentially There’ll be a part two Let’s hope [Music] [Applause] Hey [Music] So Uh [Music] [Music] [Music] Foreign