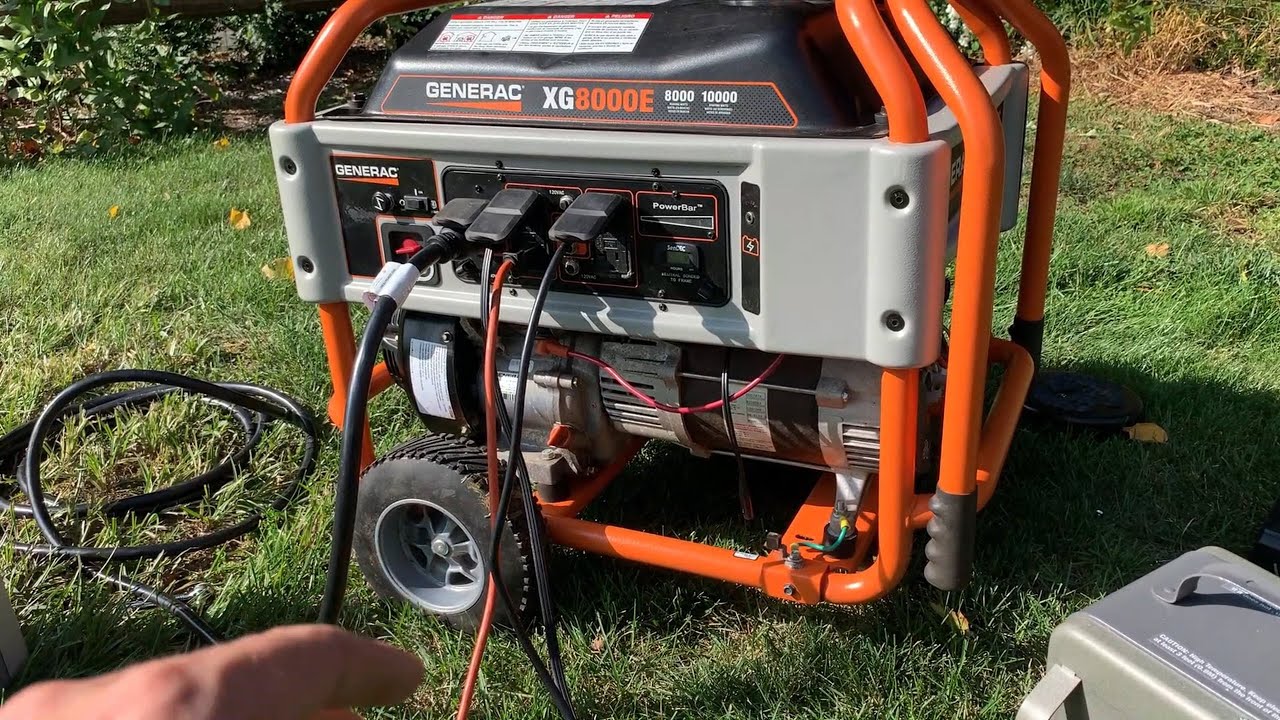

Hey guys welcome back So today i brought home this xg8000e Made by generac and you can probably Tell it's It's not in too bad of shape but it was Stored outside You know we got a bunch of corrosion Rust And dirt but overall not too bad So this machine was advertised as Non-running And for the obvious reason suspected Carburetor issues Now with that said when i went to pick It up I pulled the engine over and it started Right up And sounded pretty good so you know the Seller did have this carburetor replaced About 11 months ago so i tend to think That Most likely the carb is fine so i'm Probably going to leave good enough Alone But with that said there are a few Things that need to be dealt with The first issue is the tank thankfully It's not Too crusty and the inside looks Pretty clean but that fuel smells pretty Stale and looks it too so it's Definitely past its prime That tank needs to be drained Also this has electric start and the

Battery was also replaced about a year Ago and you can see It's not dead But it's also not engaging the flywheel Also this side plate's been removed and I think there's some missing hardware so That needs to be Reattached and the seller also mentioned The fuel line was broken And that he you know cut the end off and Just reattached it Kind of loosely so willing to bet that These lines are probably overdue Anyway and should just be replaced and Lastly Everywhere i bring this thing it leaves A trail of water It's definitely water not gas or oil so I'm not sure where that's coming from Hopefully not in the air box but I'll dig into that as well so Let me get you guys set up on a stand And Start going on this thing i'm going to Pull off the air box And get the line off the carb and i'll Just drain the tank that way Well this is a little more complicated Than i thought it was going to be Usually just remove the bolts pull the Breather line In the back and the box comes right off But In this case we got that choke linkage

On the top kind of right there So in order to get this off Really i need to pull this panel to get Better access And before this panel can be pulled both Side panels need to be detached at least On this side And before you do that that's the Support for the tank So you got to get the tank out so it's a Few more steps involved and I don't even think i need to replace the Fuel lines You know i took a closer look at them They're not cracked or dry rot and They're not petrified So when the guy said he had to cut the Fuel line and reattach it I actually think he was talking about This line here Which kind of makes sense because he has This panel off anyway this is not a fuel Line it's just the breather For the fuel tank it used to run this Way Down and under here but you can see it's Definitely been shortened So yeah this one isn't a big deal I'm going to leave this alone for now I'll leave the bolts out because I might have to pull this blower housing Anyway to fix the starter gear But to drain the fuel i'm just going to Pull the line right here

And get that tank empty Okay so we're all drained out now i'm Actually going to pull the tank so i've Already disconnected the fuel line I'm going to disconnect the breather and There's one bolt In each corner and this thing should Slide out Now the reason why i'm doing this is Because The battery is right there And i guess i could test the voltage That way but what i'm thinking is that The battery is probably low I want to charge it up i don't have the Charger that comes with this And even if i did this is a manual Charger which means It can overcharge the battery you just Want to plug it in For maybe half a day once a month to top It off So what i'm going to do is install this Charging wire For a trickle charger and this will be Automatic so it can just be left plugged In All the time and you don't have to worry About Plugging it in for too long [Music] Yeah that battery is basically dead i Think anything below like 12.2 Is considered dead so i'm going to hold

These leads on here just crank the Engine i want to see how How far that voltage drops Yeah so i'm gonna throw the charger on That for a while try it again See if it'll uh engage So while that battery is charging i'm Gonna deal with these these are just Insulators for the tank so it doesn't Rattle Too much and you can see they're pretty Uh Dry rot so i do have a bunch And i think these here are the right Size so i'm gonna Swap these out I hope Just like that so do that three more Times and we should be good I've only had this charger hooked up for About six minutes now And You can tell don't have a starter issue It was just a battery issue so At this point you know i let it cook for A bit longer but i think i'm just gonna Put the cord the charge cord on there Clean this up a bit Reinstall the tank and just trickle Charge it The rest of the way So before putting the fuel tank on i do Want to tighten this air box down These screws are pretty crusty coming

Out potentially something could break Also there were supposed to be two Screws down Here and there weren't they were Completely missing so i already started One in i've got another one here that Should fit so I'm gonna start tightening this stuff Down make sure there's no Complications before proceeding So i stopped off the auto store today to Pick up some new line for this breather And kind of struck out they had of Course plenty of lines but The diameter of the walls were too thick So either the outer diameter was wrong Or the inner And obviously the inner has to be this Size to fit here properly in the outer To go through there so you know i do Have some new line That is the right kind but I'm sure by about a foot foot and a half You know if they had routed it this way It would reach i'm not really sure why They would go all the way the wrong way Just to go to the other end regardless This isn't going to cut it the original Line is too Short so you know this is just a vent i Mean technically i could just leave it Like that But to be environmentally correct I should try to reconnect it for what

It's worth Anyway i'm gonna try to mend these two Together With some shrink tubing it's marine Grade with glue so theoretically It'll join these two uh pretty well And then i can use this combined line To vent the tank down into the air box Yeah i think that'll work just fine So Okay ready to give this thing a try not Even sure if it makes power But it should given what i see here On the meter it's 1.3 hours So technically this engine isn't even Broken in yet So i'm not going to push it too hard but You know assuming it starts and runs Sounds good and the voltage and speed Check out i'll load it up 3000 watts And just make sure that the generator Engine is able to maintain Speed and that the voltage stays good So the engine's actually maybe a little Fast The voltage a little bit low Let's try a load and see how it does Yeah so engine speed's holding good and The voltage is steady where it was Before Yeah so not too bad you know it's doing What it's supposed to do But the engine speed Is a bit fast it was around 63 hertz and

I mean it's not that uncommon i see a Lot of generators Putting out that much speed under no Load but You know i like to tone it down a bit 62 Is usually the max I i do unless there's a reason to go More than that And the voltage is it's on the low side Of passable but i do want to bring that Up a bit So what i'm gonna do is Just pop this cover off see if it has a Potentiometer and if it does we'll turn It up a bit To closer to 120 volts and as far as the Engine speed goes There is an adjustment screw Right there so that needs to be turned Counterclockwise and then We should be good Yeah and there is a potentiometer there So i'm going to give that Maybe a half turn clockwise and check The voltage see what that gives us Okay so the voltage actually went down About a volt So maybe generac does theirs differently Or maybe i'm remembering wrong So i gotta turn it half a turn Counterclockwise to get it back to where It was which is 113 volts And then i want to go up about three Volts so

I think one full turn Should do about three volts so i'm going To do two full turns Counterclockwise and see if we're closer To 120. Okay getting a lot closer so Counterclockwise on this generator is Actually To increase the voltage so i brought it Back to where we started which is the 113 Did two full turns counterclockwise to Get it To 117 so i'd say you probably need to Do at least One more full turn probably a turn and a Half Uh [Music] Okay that's pretty good right around 120 Volts I'm gonna see if i can adjust that Engine speed down a bit So So So Okay good the voltage it's now at 120 Volts And the engine speed it's a little bit Closer to What i would consider safe at 62 hertz Now i mean this generator has Practically no hours on it I'm not sure why it was running so fast

If that's how generic intended it to run At no load i Don't know but you know 62 seems safer So I'm going to go with that now I did test it obviously with the 3 000 Watt load it did Pretty well but it was a little bit Unsteady so i Threw another space heater on there Bringing it up to 4 500 watts just Wanted to make sure That the problem wasn't getting any Worse and it actually seemed To get a little bit better so i think We're good you know it runs Sounds good can support a load and the Hurts and the voltage Are good now the only last thing worth Noting on this Is the choke knob and if you've got one Like this it's a fairly common problem That this knob Can shake out when the generator is Running and in this case it's not it Stays in when the generator is running But i noticed when you go to start it A hud engine you know i leave the choke Off but when i hit start The shaking of the startup causes the Choke to come out And i didn't notice that at first so i Was kind of looking around like why is This thing running bad

But let me just show you real quick what It what it does So i don't know if that's a feature or a Flaw but I wouldn't expect that anyway i think We're done here You know this thing is doing what it's Supposed to do I hope this video helped someone thanks For watching